Chemical Engineering

- Chemical Engineering

- Department Details

- Laboratory

- Faculties

- Academic Calendar

- Syllabus

- Events

- TimeTable

- Result Analysis

- Training and Placement

- Student Notice

HOD Message

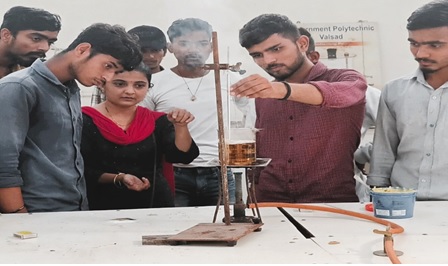

- Welcome to the Department of Chemical Engineering at Government Polytechnic Valsad. We started our journey in the year of 1970. The primary focus of our curriculum is to impart technical knowledge to students, promote their problem solving skills and innovation of new technologies. The course contents are periodically updated for introducing new scientific and technological developments.

Various activities such as expert lectures, industrial visits are carried out for technical skill development of students. Along with technical development we also focus on developing a responsible citizen by promoting awareness of safety, environmental and social issues in students.

Chemical Engineering is NBA Accredited for academic year 2022-2023 to 2024-2025 i.e. up to 30-06-2025

Vision

- To be one of the leading department in developing dynamic diploma chemical engineering professionals according to evolving industrial trends in national interest.

Mission

- To become a model department for Outcome Based Education by adopting best practices and improving infrastructure.

- To develop critical thinking, problem solving skills and interpersonal skills in students to overcome professional challenges by cultivating a proactive learning environment.

- To impart affirmative traits and productive mindset to the students by exemplary mentoring.

- To collaborate with industries to achieve employer focused learning by regular industrial visits,vocational training and expert lectures.

- To develop responsible citizenship in students by promoting awareness of safety, environmental and social issues.

Program Educational Objectives (PEOs)

- To develop knowledge for overcoming challenges in the area of chemical engineering.

- To develop ability to successfully execute skills in operation of chemical plants with help of industry institute interaction.

- To develop professionals who will thrive to pursue skills of problem solving, communication, team work, life-long learning, leadership, professional ethics and values.

Program Specific Outcomes (PSOs)

- An ability to apply safe work practices in chemical manufacturing processes.

- An ability to apply chemical engineering principles for environment protection.

- Best Practices by Institute

Mrs.Chauhan Sejal Mahendrasinh

Lecturer(Regular)

M.E. Chemical Engg. (Petrochemical)

Joining Date:06-08-2015

MECHANICAL OPERATION LABORATORY

The course covers the hands-on experience of working by conducting experiments on most of the basic unit operations like Jaw Crusher, Roll Crusher, Ball Mill, Cyclone Separator, Sieve Shaker, Plate and Frame Filter etc.

FLUID FLOW OPERATION LABORATORY

It is an introductory course where flow behaviour, fluid forces and analysis tools are introduced. The goals of the experiments include determination of forces generated when fluid flow takes place over a solid object, applications of the control volume approach, demonstration of the momentum and energy equations, viscosity measurement and engineering correlations. Intricate flow phenomena such as separations and transition to turbulence are demonstrated. Experimental setups such as Reynolds Number, Hydraulic Bench, Bernoulli’s Theorem, V notch, rectangular notch, venture flow meter etc. are made available to the students.

HEAT TRANSFER LABORATORY

Heat transfer laboratory is an undergraduate teaching laboratory housing a handful of experimental setups pertaining to fundamental heat transfer problems and their applications. Experimental setups such as Emissivity, Metal Rod, Composite Wall, Insulating Material, Shell and Tube Heat Exchanger, Free Convection, Force Convection, Stephen Boltzmann etc.

MASS TRANSFER LABORATORY

The purpose of this lab is to introduce the undergraduate students to the most important separation equipment in the process industry and provide a hands-on training of the proper operation of these units. This helps in not only understanding the theoretical fundamentals of the subject but also helps to visualize its real-world applications in the process industry. This laboratory covers the following experiments: Vapour Liquid Equilibrium, Absorption Packed Tower, Electric Oven, Swenson Walker Crystallizer, Solid-Liquid Extraction, Packed Bed Distillation and Distillation with DCS etc.

UTILITIES AND INSTRUMENTATION IN CHEMICAL PLANT LABORATORY

Utilities and instrumentation in chemical plant laboratory Equipped with Experiments like Level Controller, Temperature Controller, DCS and SCADA system, pH meter, Hygrometer, Hydrometer.

PETROLEUM REFINING AND PETROCHEMICAL LABORATORY

PRPT LAB Equipped with Petroleum Product testing Equipment's like Pensky Martine for Flash and Fire Point, Smoke Point, penetrometer, Softening, Condrason Carbon Residue etc. for better understanding of the course.

PROCESS LABORATORY

This laboratory is equipped with Glass wares with required utilities used to teach students the practical applications of courses like Chemical Process Technology, Pollution Control & Effluent Treatment, Safety & Hazard Management, Pollution Control & Effluent Treatment and Fertilizer Technology.

| Sr. No. | Notice Title | Date | View |

|---|